HEAT EXCHANGERS

HEAT EXCHANGERS MANUFACTURER: A WIDE CHOICE OF THERMAL EXCHANGE SOLUTIONS

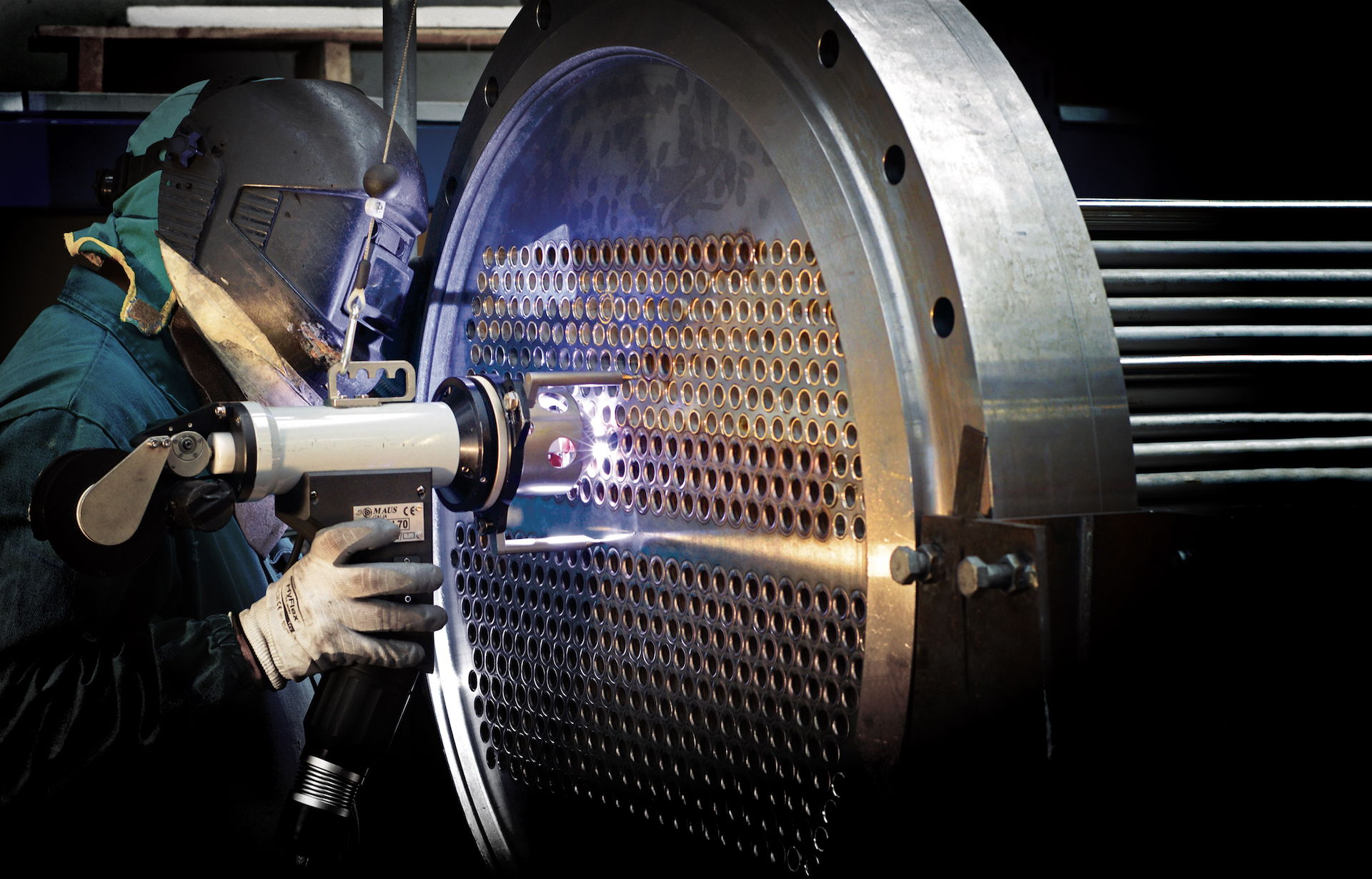

Cosmec can design and manufacture Shell & Tube Heat Exchangers for Oil & Gas and Power Generation -Cogeneration applications.

Our Technical Department perform in-house both Thermal and Mechanical Design in complete agreement with all Customer’s requirement and specification, finding the best solution in order to optimize performance and reduce sizes, weights and consequently selling price.

TEMA Type – Shell & Tube Heat Exchangers

These kinds of Heat Exchangers allow to easily exchange heat between two fluids using tube bundles

collected in a cylindrical shell/body.

Following the “Tubular Exchangers Manufacturing Association” Standards, Cosmec can select, design and manufacture the best TEMA Type choosing from AEL, AEM, AEN, AES, AEU, AEW, AJS, AXS, BEM, BES, BEU, BKU, CEM, CEN, CEU, NEN, NKU configuration. From application/service point of view, our range covers condensers, reboilers, coolers and steam generators.

DOUBLE PIPE / MULTITUBES HAIRPIN Type – Heat Exchangers

Similar to Shell & Tube Heat Exchangers, this particular solution allows a very efficient flow, since they realize a pure counter-current flow between the fluids thanks to their layout. They are generally selected for reduced exchange surfaces and can be equipped with plain or finned tubes. Hairpin type has peculiar technical features which require accuracy during manufacturing process, especially for channel and seals configuration. Cosmec has achieved the necessary experience in order to guarantee the best thermal design and construction practices.